Factory

Factory

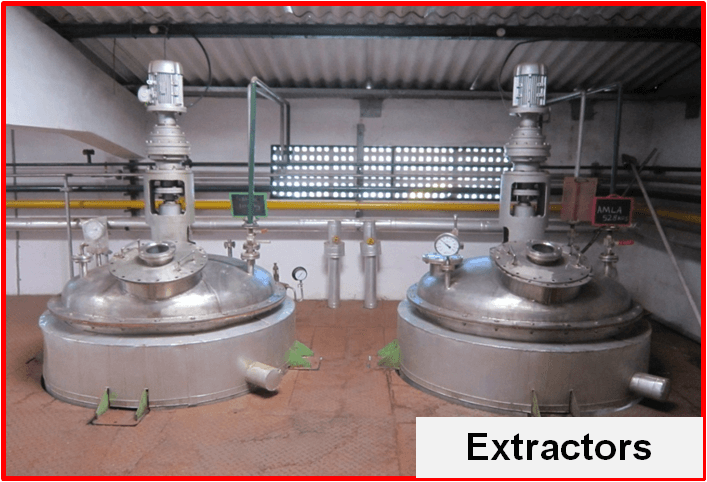

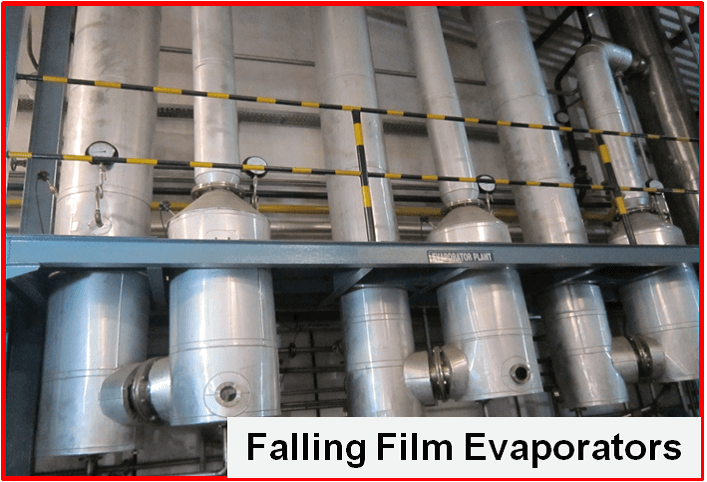

Vivaan's manufacturing plants are fully GMP compliant and have state-of-the-art manufacturing equipment. We have modern manufacturing facilities to support its businesses and strategic alliances with outsourcing partners for state-of-the-art specialized facilities. The Extraction process is carried out with adequate care and strictly as per the requirement of a particular product. Extracts are concentrated at low temperatures, ensuring that the active ingredients retain their character and undesired artifacts are not formed. Drying of Extracts is carried out in Spray/Vacuum Dryers under hygienic conditions. We have been involved in the manufacturing and exporting Herbal Extracts and Formulations since 2013.

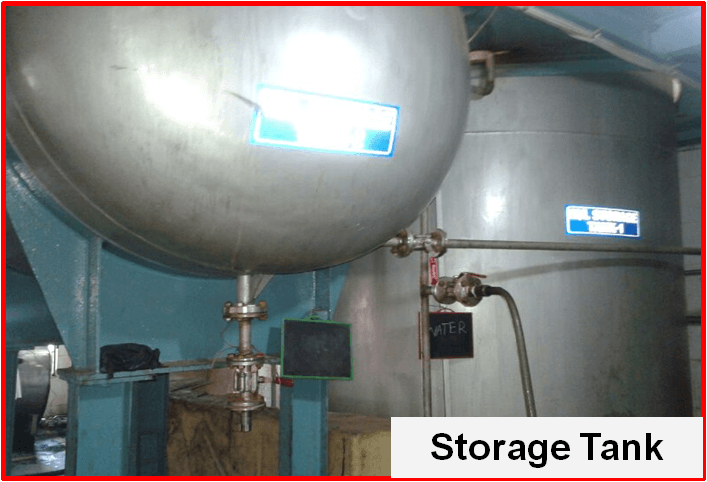

We have multi-facilities with SS electro-extraction reactors, SS filters & sparklers, chilling and evaporation, centrifuging facilities, crushing facilities, granulation & blending facilities, spray drying, integrated water system, waste treatment and packaging. The company is positioned to offer clients end-to-end high quality products and optimised production practices.

Our manufacturing facilities have a capacity to produce over 300 MT of standardized extracts the year around. The facility has a dedicated Spray-Drying Unit that is designed to meet the highest quality standards and optimise product-drying yields with improved density control.

We adopt improved manufacturing practices that are in line with global manufacturing standards and natural product requirements with teams of highly qualified and trained technologists who are backed with a refined manufacturing culture.

Stringent process control measures are imposed to impart consistency and reliability to every act in the manufacturing process. Clean environments, uninterrupted power supply, a strong EH&S policy, information and technology automation, besides a team of natural product engineers who ensure high quality manufacturing practices.